Extraction

of Caffeine/Coffee Oil Using Liquid-Liquid Extraction

Introduction

Caffeine is known medically as trimethylxanthine and

possesses the chemical formula C8H10N402. It

occurs naturally in over 60 plants, including coffee beans, tea leaves and cocoa

nuts. In its pure state, it exists

as a bitter white powder. Caffeine

is used in the medical field as well as food processes. Medically, caffeine is used as a cardiac stimulant and a mild

diuretic. In the food industry,

caffeine is marketed as a means to boost energy. It can be found in most type of colas, coffee, tea and

chocolate products. Caffeine is

also prevalent in over-the-counter stimulants, such as Vivarin and NoDoz.

The primary source of pure caffeine is the process of decaffeinating

coffee and tea.

Proposed

Design Problem & Solution

There are 2 methods of decaffeinating coffee, the

indirect and direct means. The

indirect means uses water as the decaffeinating agent.

It is passed through the coffee beans and released into a separate

chamber. There, it is

decaffeinated. The water is then

returned to the coffee to restore its natural flavor.

The direct method mixes an organic decaffeinating agent, such as

dichloromethane, ethyl acetate or supercritical carbon dioxide, directly with

the coffee. The caffeine binds to

this substance and then is removed from the coffee, usually through boiling.

The direct means of decaffeinating is the process we choose to replicate.

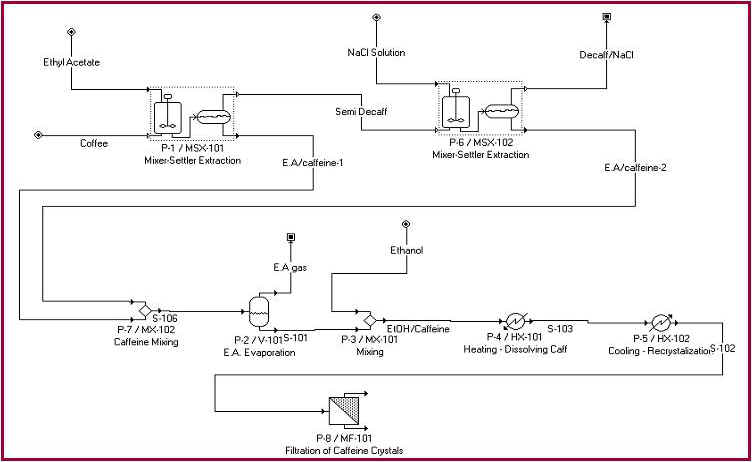

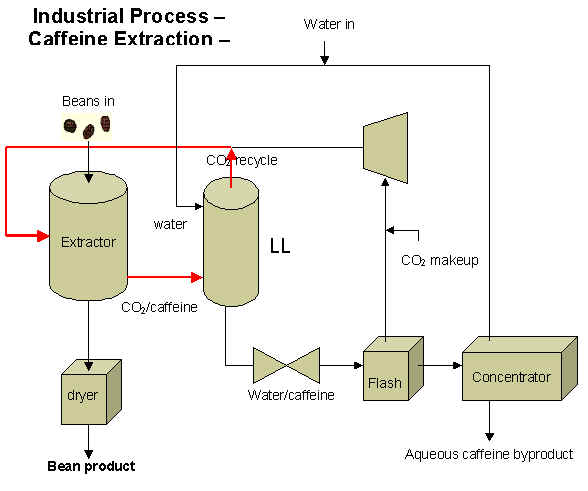

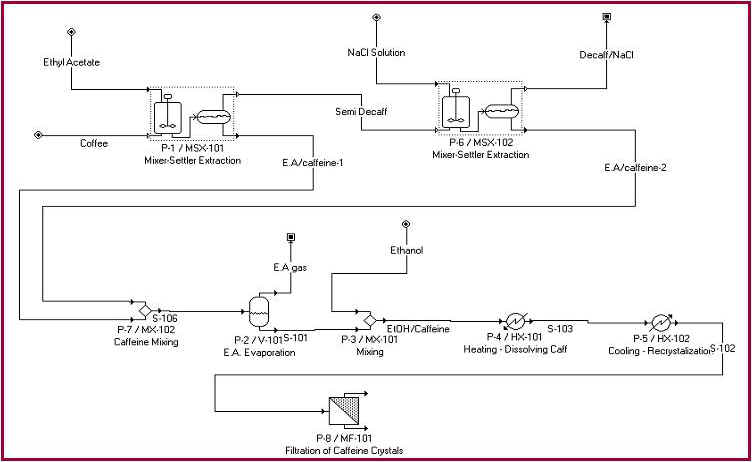

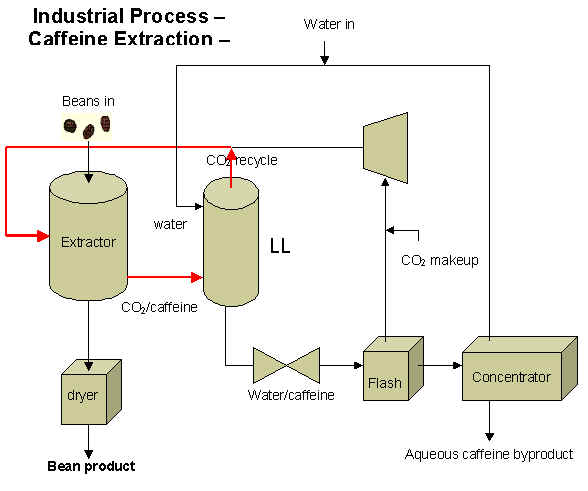

Detailed

Flow Chart from SuperPro

The various steps in the decaffeinating process can be

found in the SuperPro flowchart in Appendix A.

Literature

Review

Fourier

transform infrared determination of caffeine in roasted coffee samples

Fresenius

Journal of Analytical Chemistry (2000) 366: 319-322

Coffee contains several alkaloids, caffeine being the most important one.

For consumer information, it is required to accurately determine the

caffeine concentration in commercially roasted coffee.

A new procedure has been developed for the Fourier transform infrared

(FT-IR)

determination

of caffeine in roasted coffee samples.

It uses the same type of decaffeinating agents we used in our

experimental procedures. The CHCl3

extracted the caffeine from the wetted coffee samples.

The FT-IR procedure then measured absorbance to determine the

concentration of caffeine in the coffee. The

extraction of caffeine by organic solutions was successful in this study, which

furthered our hypothesis that caffeine could be obtained using this type of

process in our experimental process.

Effects

of caffeine, caffeine-associated stimuli, and caffeine-related information on

physiological and psychological arousal

Psychopharmacology

DOI 10.1007/s002132100841

Caffeine is a known stimulant. The

study conducted in this journal article tested the physiological and

psychological effects caffeine had on various individuals.

The caffeine-associated stimuli increased alertness, contentedness and

skin conductance levels. The

information that the drink contained caffeine alone decreased calmness in the

subjects. Decaffeinated drinks (including coffee) were placebos given

to subjects. After consumption,

increased contentedness was reported. The

authors concluded that the caffeine-associated stimuli increased arousal and

information about the content of the drink modulated arousal in the direction

indicated by the information. The

caffeine evidently effected the subjects and the time and research put into this

study show the demand for caffeine on the market as well as decaffeinated

products.

Mauldin,

R.F., Burns, D.J., Keller, I.K, Koehn, K.K., Johnson, M.J, Gray, S.L. Theory

of

Supercritical Fluid Extraction via the Discovery Approach Chem. Educator. 1999,

183-185.

Supercritical CO2 is a new technology that is being explored

for the use in extraction. It

involves high pressure CO2 which can be used to extract organic

compounds, like caffeine or nicotine. This

can be used to obtain a product, or be used to take the product out, like for

the decaffeination of coffee. This

is a very good alternative to other extraction methods because it is non-toxic

and easy to separate from the product of interest.

Sarmento,

M., Pires, M., Cabral, J., and Aires-Barros, M.

1997. Liquid-liquid

extraction of a recombinant protein, cytochrome b5, from an impure extract using

aqueous two-phase systems. Bioprocess

Engineering. 16: 295-297.

Liquid-liquid

extraction is used extensively in chemical and pharmaceutical industry, though

it was not until recently that this technique has been used to recover

bipolymers (proteins) because of their low solubility in organic solvents and

the denaturing effect the solvents have on the structure of the protein

A

two-phase system of polyethylene glycol and potassium phosphate salts were used

to perform a liquid-liquid extraction of cytochrome b5 from sheared Escherichia

coli cells. This extraction

process was a single step process that allowed the complete removal of cell

debris and a nearly 67% recovery of the target protein from the aqueous layer.

.

Experimental

Plan:

The unit operations we choose to run in the laboratory included mixing,

settling and pumping a variety of materials different places.

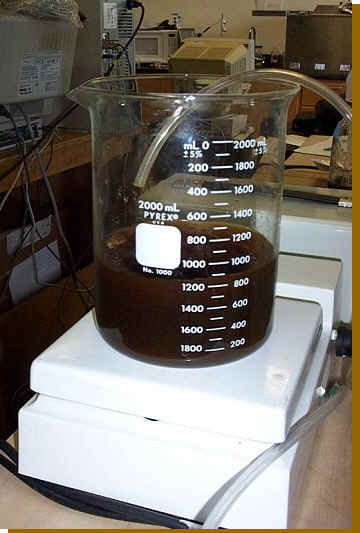

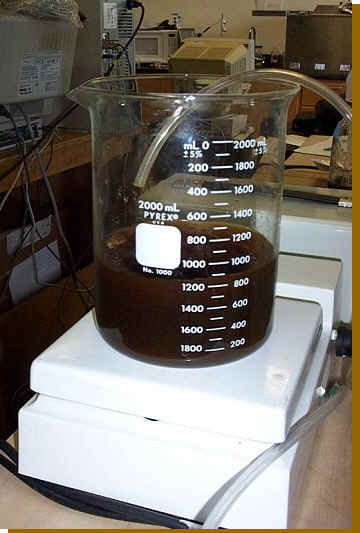

A large vessel was required for the mixing of the coffee with the

saturated NaCl solution and the ethyl acetate.

It was placed on a stir plate with a stir bar for 10 minutes.

Once the solution was completely mixed, it was pumped into a smaller

settling vessel. Here, two distinct

layers formed due to the differences in densities. The oily organic layer, which contained the caffeine, was

found on top. This layer was pumped

into another vessel. The remaining

layer was the decaffeinated coffee. This

coffee, in industry, would be purified to remove any remaining decaffeinating

agent. The oily organic layer was

then boiled to remove the decaffeinating agent, ethyl acetate.

Pure caffeine was not obtained at this time due to the fact that the

caffeine was still suspended in the oil. The

oil would need to be evaporated, and then the caffeine would need to be

re-crystallized in order to obtain pure caffeine.

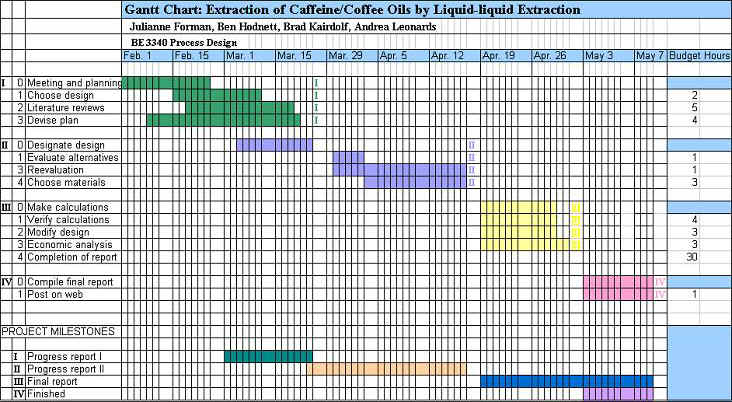

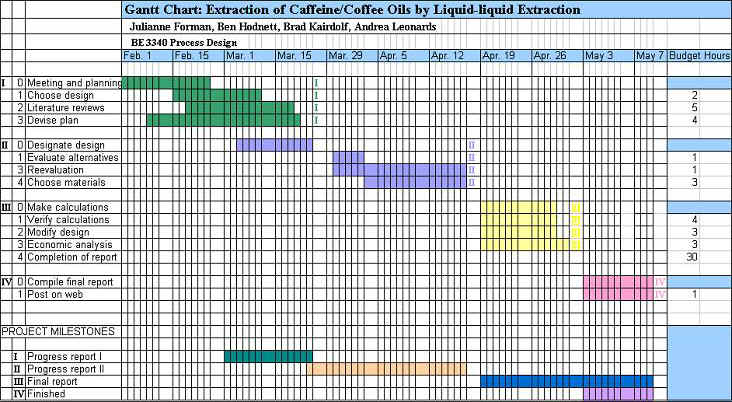

Updated

Gantt Chart

– See Appendix B

Results

and Discussion:

Our experiment demonstrated a successful set-up and was triumphant in

removing caffeine from the coffee, however we did not obtain pure caffeine.

The caffeine was trapped inside the oil instead of binding only with the

ethyl acetate. Further unit

operations would have been required to achieve pure white powder caffeine.

This process proved to be an effective way to remove caffeine from

coffee. On the other hand, a more

effective means may eliminate the oily layer and have the caffeine only in

solution with the ethyl acetate. The oils extracted by the ethyl acetate were an unexpected

problem, but it did not affect the decaffeinating process greatly.

Economic

Analysis:

The

equipment used for our unit operations included a mixer and three pumps.

All materials were scaled up using the appropriate formulas and a cost

analysis was performed. The basic

formulas and results are found in the chart below while all the details of the

calculations can be found in Appendix C.

|

|

Scale Up Factors

|

Cost Analysis

|

|

Agitator

|

|

|

|

Pump 1

|

|

|

|

Pump 2

|

|

|

|

Pump 3

|

|

|

|

Total Cost

|

|

$221,440

|

Appendix

Appendix A:

Appendix B

Appendix C

Scale-up

of Agitator

Density of ethyl acetate = 894.5

kg/m³

Dynamic Viscosity of ethyl acetate

= 0.426 x 10-3 Pa·s.

Density of water = 1000 kg/m³

Dynamic Viscosity of water = 0.86 x

10-3 Pa·s

Density of saturated salt solution

(NaCl) = 1100 kg/m³

Dynamic Viscosity of saturated salt

solution = 0.89 x 10-3 Pa·s.

Density of mixture (water/saturated

salt solution) = 1050 kg/m³

Dynamic Viscosity of mixture

(water/saturated salt solution) = 0.9 x 10-3 Pa·s.

Volume of mixture (water/saturated

salt solution) in lab scale = 350 mL.

Volume of ethyl acetate in lab

scale = 100 mL.

Total volume in mixing chamber in

lab scale = 450 mL.

Approximate density of fluid in

mixing chamber = (1050 kg/m³) · (0.777) + (894.5 kg/m³) · (0.222) = 1015

kg/m³.

Approximate dynamic viscosity of

fluid in mixing chamber = (0.9 x 10-3 Pa·s) · (0.777) + (0.426 x 10-3

Pa·s) · (0.222) = 0.795 x 10-3 Pa·s.

Volume of lab scale reactor = 500

mL.

Diameter of reactor = 8 cm = 0.08

m.

Diameter of impeller = 2 in =

0.0508 m.

Speed of lab mixer = 30 rpm = 3.14 rad/s.

è

Re = 20701 = 2.1 x 104 è

turbulent è

assume Np’ = 5.

è

Re = 20701 = 2.1 x 104 è

turbulent è

assume Np’ = 5.

è

P = 0.05 W = scale power.

è

P = 0.05 W = scale power.

è

tm = 1.9 s.

è

tm = 1.9 s.

Since keeping the time on scale-up is not feasible, we

scaled up our mixing time to 20 s. Using

a new mixing time, we had to calculate a new impeller speed.

Using a scaled-up vessel (3-m radius by 5-m height), a

scaled-up impeller diameter of 2.5 m, and the scaled-up time of 20 s, we were

able to calculate our new Ni.

è

Ni = 0.67 rad/s = 6.4 rpm.

è

Ni = 0.67 rad/s = 6.4 rpm.

è

Re = 5.36 x 106. Use Np’

= 5.

è

Re = 5.36 x 106. Use Np’

= 5.

è

P = 149200 W = 200 hp.

è

P = 149200 W = 200 hp.

Cost –

Analysis of Agitator

Our scaled-up agitator will be a single blade Rushton

turbine.

Base cost of 200 hp agitator (dual turbine read from chart)

è

$90,000.

Fmod = 2.0

Fm for single blade turbine = 0.82

CIpresent = 392.7, CIbase = 324

è

$178,897.

è

$178,897.

Scale-up of

Pump 1 (from mixer to settler)

The volumetric flow from mixer to settler was selected as

0.1 m³/s. The pipe diameter was

selected as 10 cm = 0.1 m.

= (0.1 m³/s) · (1015 kg/m³) è

101.5 kg/s

= (0.1 m³/s) · (1015 kg/m³) è

101.5 kg/s

è

0.0078 m³.

è

0.0078 m³.

Q = v · A è

v = 12.73 m/s

Leq = 3 · 35 · 0.1 + 0.5 + 5 = 16.0 m

è

Re = 1.6 x 106 è

turbulent

è

Re = 1.6 x 106 è

turbulent

è

f = 0.0275

è

f = 0.0275

è

142.6 m²/s²

è

142.6 m²/s²

è

ws = 223.6 m²/s²

è

ws = 223.6 m²/s²

= 22.79 m

= 22.79 m

For the following brake horsepower calculation, we chose

our pump efficiency to be 0.5. This

was done to give an overestimate of cost, rather than an underestimate.

Brake hp =

è

45384.7 W è

60.9 hp

è

45384.7 W è

60.9 hp

Cost – Analysis of Pump 1

Our scaled-up pump will be a turbine with a brake

horsepower of 60 hp.

Base cost of turbine = $7000.

Fmod = 1.80

Fm = none

è

$15,272

è

$15,272

Scale-up of

Pump 2 (from settler (ethyl acetate))

The volumetric from mixer to settler was calculated to be

22% of the original flow or 0.022 m³/s. The

pipe diameter was selected as 5 cm = 0.05 m.

= (0.022 m³/s) · (894.5 kg/m³) è

19.7 kg/s

= (0.022 m³/s) · (894.5 kg/m³) è

19.7 kg/s

è

0.002 m³.

è

0.002 m³.

Q = v · A è

v = 11.2 m/s

Leq = 5 · 35 · 0.05 + 1 + 4.75 + 1 +5 = 20.5 m

è

Re = 1.2 x 106 è

turbulent

è

Re = 1.2 x 106 è

turbulent

è

f = 0.003

è

f = 0.003

è

301 m²/s²

è

301 m²/s²

è

ws = 366 m²/s²

è

ws = 366 m²/s²

= 37.31 m

= 37.31 m

For the following brake horsepower calculation, we chose

our pump efficiency to be 0.5. This

was done to give an overestimate of cost, rather than an underestimate.

Brake hp =

è

14420.8 W è

19.3 hp

è

14420.8 W è

19.3 hp

Cost –

Analysis of Pump 2

Our scaled-up pump will be a turbine with a brake

horsepower of 19 hp.

Base cost of turbine = $4000.

Fmod = 1.80

Fm = none

è

$8727

è

$8727

Scale-up of

Pump 3 (from settler (wastage))

The volumetric from mixer to settler was calculated to be

78% of the original flow or 0.078 m³/s. The

pipe diameter was selected as 7.5 cm = 0.075 m.

= (0.078 m³/s) · (1050 kg/m³) è

81.9 kg/s

= (0.078 m³/s) · (1050 kg/m³) è

81.9 kg/s

è

0.0044 m³.

è

0.0044 m³.

Q = v · A è

v = 17.6 m/s

Leq = 3 · 35 · 0.075 + 1 + 5 = 13.875 m

è

Re = 1.54 x 106 è

turbulent

è

Re = 1.54 x 106 è

turbulent

è

f = 0.0278

è

f = 0.0278

è

318 m²/s²

è

318 m²/s²

è

ws = 473.3 m²/s²

è

ws = 473.3 m²/s²

= 48.25 m

= 48.25 m

For the following brake horsepower calculation, we chose

our pump efficiency to be 0.5. This

was done to give an overestimate of cost, rather than an underestimate.

Brake hp =

è

77531.9 W è

103.9 hp

è

77531.9 W è

103.9 hp

Cost – Analysis of Pump 3

Our scaled-up pump will be a turbine with a brake

horsepower of 100 hp.

Base cost of turbine = $8500.

Fmod = 1.80

Fm = none

è

$18,544

è

$18,544

Total

Cost = $221,440

Our Settling Tank

Our Mixing Tank

Chemicals

of Interest

References

Doran, Pauline M. Bioprocess

Engineering Principles. Academic Press, San Diego: 1995.

http://www.sciam.com/0697issue/0697working.html

http://antoine.frostburg.edu/chem/senese/101/matter/faq/decaffeinating-coffee.shtml

http://www.cariboucoffee.com/aco.cfm?ct=a

Walker, Terry. BE 3340: Process Design in Biological Engineering.

2002.

Garrigues, Jose M., Zouhair

Bouhsain, Salvador Garrigues and Miguel de la Guardia. “Fourier transform

infrared determination of caffeine in roasted coffee samples”, Fresenius

Journal of Analytical Chemistry.

Mikalsen, Anita, Bard Bertelsen

and Magna Arve Flaten. “Effects of caffeine, caffeine-associated stimuli, and

caffeine-related information on physiological and psychological arousal”, Psychopharmacology.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()